On-site visits

On-site visits

Specialists of Meridian Company are highly competent and mobile. At any time convenient for our customers, they are ready to come to customers’ sites to provide samples of workwear and footwear and to negotiate and discuss details of cooperation and execute any documents required. This service is in great demand among our customers since it significantly facilitates the process of selection of safety outfit for staff of companies and allows us to promptly solve any issue.

Whatever the distance, our cooperation will still be effective. We are always ready to provide a complete package of services in supplying workwear, footwear and personal protective equipment.

Oursourcing

Oursourcing

Organization of standalone warehouses is an efficient format of rendering services in supplying personal protective and safety equipment. Meridian Company has developed and is successfully implementing a project of cooperation with such PPE storage and dispatch centers located both at customers’ sites and at other locations.

Types of Services

Outsourcing

is a comprehensive program which helps to meet 100% of a company’s need for workwear, safety footware and PPE in accordance with standard norms for provision of PPE by occupations and pursuant to corporate procedures approved for every facility.

Consignment (warehouse stores)

is a form to delivery of goods for consignment storage with their further sale at the facility.

Problems to be soled within the framework of the projects

Outsourcing

- 100% avaiability of everything required is ensured by automated planning based on standards adopted by the company and personal (anthropometric) data of its staff members;

- Scheduled deliveries and quality control;

- Arrangement of PPE storage and dispatch centers;

- Delivery of notices of scheduled issue of PPE to staff members;

- Feedback from staff members;

- Prompt introduction of new workwear items and new types of PPE

Consignment

- 100% availability of everything required;

- Scheduled deliveries to facilities;

- Prompt introduction of new workwear items and new types of PPE

Additional services

Outsourcing

- Washing and minor repair of workwear;

- Labeling of workwear;

- Automatic PPE dispensing machines;

- Disposal of PPE

- Guest lockers

Major advantages

Outsourcing

- 100% availability of PPE;

- Absence of leftover PPE stock at warehouses, and release of operating assets;

- Payment only upon actual issue of PPE by the customer to its workers;

- Prompt introduction of new workwear items and new types of PPE;

- Release of human resources engaged in the process of PPE procurement;

- Recording of PPE issued in Personal Employee’s Record;

- Use of field-specific software for planning of needs and accounting;

- Elimination of leftover stock

Consignment

- 100% availability of PPE;

- Absence of leftover PPE stock at warehouses, and release of operating assets;

- Payment only upon actual issue of PPE by the customer to its workers

You can send us a request for presentation or ask any question you have.

Please leave your contact detailsand our specialist will contact you.

Fill in the fields or call the number

8 (831) 465-42-34 (add. 1181)

From sketch to finished product

From sketch to finished product

All pieces of workwear and footwear are devised, designed and developed by the “Creative Laboratory” of Meridian Company.

Our specialists develop and implement up-to-date workwear and footwear design and manufacturing technologies. At the same time, all the priorities are set according to customer’s requirements and taking into account specific features of the field of their business and current standards and technical specifications.

Development of model ranges of worwear and professional clothing

Our design department solves the entire set of problems of development of new model ranges. The set includes automated design, utilization of engineering and design solutions with further development of documents, layout and printing of templates, and selection of materials and components. All products are sewn at our test and development facilities, where all units and elements of industrial-grade cutting and sewing processes are perfected. All lines of workwear are made on the basis of pilot samples.

Creating safety footwear collections

Development of safety footwear starts with sketching of future models. After that, workpieces are made to test and develop the models and all required documents are drafted. After making a pilot sample, our specialists perform quality assessment pursuant to regulations and standards and test the products for their conformity to the operating requirements. Findings of such assessment are executed as quality certificates for each footwear sample. Only certified samples are launched into mass production. All products of JSC Meridian are covered by certificates of conformity and laboratory test reports supporting their protective properties.

Trial wearing

Trial wearing before buying is an effective way to check the quality of workwear and safety footwear. A customer sends us a request specifying the expected protective properties, operating temperatures, work conditions, and basic materials for the workwear or footwear ordered. Results of trial wearing are executed as an expert opinion on product quality. Such opinion can also include comments on the model, which we use to perfect our products. We, as a manufacturer, see this as the surest and shortest path to improvement of our production.

Corporate Style

Corporate Style

Our corporate clothing collections and catalogs are developed in line with brand style of our customers.

Corporate clothing is a part of the corporate culture, the most important component of a successful company’s image and its signature style. Workwear should be both comfortable and easy to recognize. It should show that a person is employed with a certain company. Moreover, it should be the determining factor in the first impression a customer gets about the company. Today, it’s obvious that a company should distinguish its employees among thousands of others by creating its own catchy style. “A book is often judged by its cover”, as they say.

Corporate workwear is more than just a sign of employment with a certain company. It is a message sent by te employee wearing it to each customer. This message incorporates multiple elements, which will add up to ensure success if your choice of workwear has been well-thought-out. That is why development of a brand style (including corporate clothing for your staff) is among the most important steps which can become a turning point in your business.

JSC Meridian has determined the top priority priniple of its operation – we use individualized approaches to our customers and focus on creating corporate clothing. We design comprehensive workwear collections and, thus, development of corporate catalogs are among the most important lines of our activity. During the 30 years of operation, we have gained extensive experience and deep insights in this field. Upon customer’s request, we can make models of any complexity class and in any modification provided by a respective catalog. Furthermore, we are ready to develop new models and manufacture customized models under customer’s sketches and technical specifications. We have an in-house design team, design and process services, R&D shop, our own production facilities, and a well-arranged system of cooperation with our customers. Therefore, our specialists can meet the most demanding requirements to professional clothing and workwear. We discuss specific features of production processes, materials and accessories, color schemes and options of application of company’s brand logos with the customer. We do understand the importance of the appearance of the staff, and we are ready to solve the complex issue of development and sewing of corporate clothing.

Development of technical specifications

Development of technical specifications

JSC Meridian offers professional services in development of technical specifications for general use products. We are ready to develop and deliver the entire set of documents in compliance with current legislative requirements.

A technical specification is a document developed on the basis of a relevant decision made by the developer and/or manufacturer or upon customer’s (end user’s) request. A technical specification is a kind of a corporate standard, that is a document regulating manufacturing, control and acceptance processes and product quality requirements.

Technical specifications are required:

- If there is no national standard (GOST) for the product, or if the specific features and the range of products provided by such national standard are not enough;

- If a product provides different types of protection and a technical specification is required for certification of such product;

- If novel technology is used and up-to-date quality standards are implemented. At the same time, such technical specification should be based on relevant requirements set forth in applicable GOSTs;

- For corporate clothing, when it is required to provide comprehensive description of requirements to the appearance, design, materials and protective properties of products in line with the company’s “corporate” standard.

Stages of development:

- Preparation and getting a statement of work specifying requirements to protective properties, design, materials etc. with breakdown by operations and specialties;

- Development of models (sketches) of workwear; and approval of such sketches;

- Selection of materials and components in accordance with the requirements to protective properties of future products and in line with the corporate style; and approval of such materials and components;

- Sewing and presentation of pilot workwear samples by the Contractor, which are made in accordance with models approved by the Customer;

- Trial testing (wearing) of workwear at the production facility ordering it;

- Correction of any remarks; making modifications on the basis of findings of such on-site tests; approval of samples; and manufacture of reference product samples; and

- Development of technical specifications by the Contractor and their approval by the Customer; and registration of such technical specifications with competent authorities.

Product Branding

Product Branding

Clothing with company’s logo is the best ads. Branding is one of the most effective advertising tool, and printing logos on clothing is the most popular branding option.

Logos can be applied both at the stage of cutting and to finished products and headdresses (including workwear, uniform, jackets, vests, T-shirts, polo shirts, promoter’s uniform, baseball caps, visor caps, bandanas etc.).

Branded clothing not only maintains the corporate style and promotes company’s image but also is an excellent marketing solution attracting attention of prospective customers.

Methods of application of logos to clothing

We offer services in applying brand logos at the stage of cutting and to finished products using up-to-date product branding techniques and methods. Our production capacities allow us to properly and promptly handle orders of any complexity.

Various techniques are used to apply logos to fabrics including:

- Digital embroidery

- Direct stencil screen printing (silk screen printing)

- Thermal printing (thermotransfer, hot seal (Flex tape), sublimate printing)

Digital embroidery

Our Company has a set of embroidery machines manifactured by Tajima Company (Japan), which combines high technologies, heavy duty, and a wide variety of opportunities. For digital embroidery, we use only highest quality purpose-specific threads manufactured by Maderia, Gunold, Royal, Durak and Marathon companies with a rich pallet of shades, tints and tones. We use silk, viscose, polyester, flame-resistant, metallized and fluorescent threads. Our automated process control system provides for production of thousands of items within several hours.

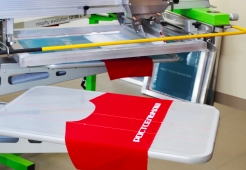

Stencil screen printing

The stencil screen printing shop is equipped with up-to-date professional equipment for the entire printing process, from photographic readout to final impression:

- Photographic equipment and devices preparing printing forms

- Automated and manual screen printing carousels

- Heat press machines

- Field-specific driyers (intermediate dryers and tunnel dryers)

Our Company uses equipment manufactured in Portugal (ACOSGRAPH, ROQ).

Logos are applied using high-quality water-based, plastysol, solvent, sublimate dyes and dyes for transfer printing, and expendables manufactured by European companies (Manoukian & Argon, Sericol International etc.). The logo application process (including printing and drying) is tested and controlled at all its stages.